Methaldehyde has excellent physical and chemical properties, that is good solubility, low boiling point, and water compatibility can be widely used in cosmetics, pharmaceuticals, household goods, automotive supplies, pesticides, leather polish, cleaning agents, rubber Industrial, paint, paint, ink and other products, but also because the methyl acetal has a good ability to oil and volatile, as a cleaning agent can replace F11 and F113 and chlorine solvent, it is an alternative to freon, reduce volatile organic compounds (VOCs ) Emissions of environmentally friendly production.

As the methyl acetal and water, methanol to form azeotrope, the traditional distillation method can only get about 92% of the methylaldehyde ternary azeotrope. However, in the methylal industry, in addition to part of the solvent uses 85% -93% purity, the rest need more than 99% purity of the methyl acetal products. At present, the industrial formaldehyde refining methods are mainly salt distillation, liquid-liquid extraction, ion exchange, adsorption and pressure distillation method. The characteristics of these methods are summarized as follows:

| No. | Process | Feature |

| 1 | Salt distillation method | The separation process is complex and the operation is demanding Waste treatment is complex, has been gradually eliminated |

| 2 | Liquid - liquid extraction | Through the introduction of the third component refined methyl acetal, need to supporting the extraction agent recovery device Disadvantages: equipment investment, operational energy consumption, the introduction of new impurities into the product |

| 3 | Ion exchange method | The crude acetal crude product has passed the strong alkaline anion exchange resin column, strong acid cation exchange resin column to obtain high purity products Disadvantages: limited processing capacity, resin recycling costs are high |

| 4 | Adsorption method | The separation of the alcohol and methyl acetal by molecular sieve was used to separate high purity methylal Disadvantages: limited handling capacity, one-time investment in adsorbents and high regeneration costs |

| 5 | Transformed distillation | The use of atmospheric pressure and high pressure, methyl acetal/methanol/water azeotropic composition changes, to achieve methylal refining The separation efficiency of the equipment is relatively high |

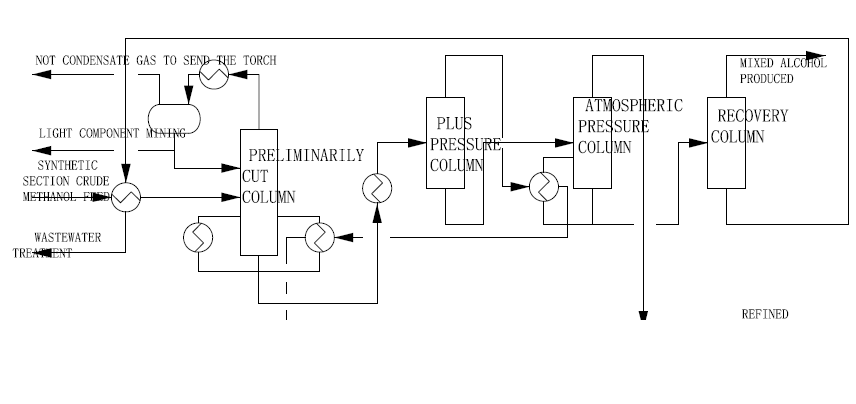

Our company's methyl acetal technology, according to the customer's requirements for the purity of methyl acetal products to pressure-based distillation to add the method to add.

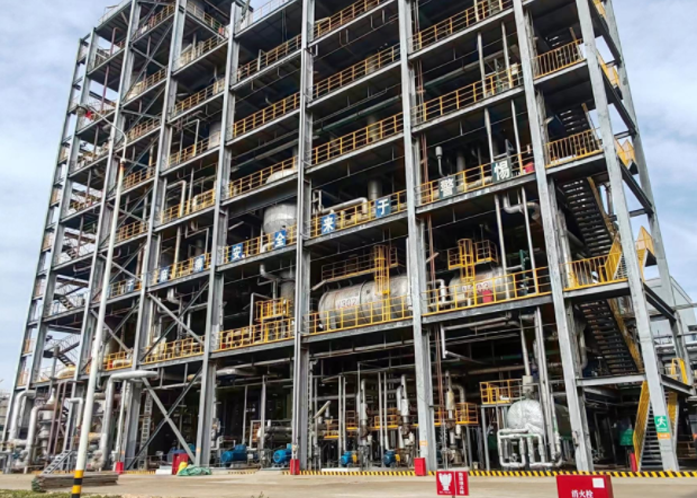

Glyphosate by-product 50,000 tons / year acetal refining device as an example.