Polyoxymethylene with low degree of polymerization has a higher content of active components than Industrial formaldehyde, and it is in the form of solid particles, which is convenient for storage and transportation. It is conducive to chemical synthesis, pharmaceutical and other industrial applications, especially when it is required to use anhydrous formaldehyde as raw material for synthesis.

The main uses of low polymerization degree POM are as follows: :① Pesticides: used to synthesize acetochlor, Butachlor and glyphosate, the amount of which accounts for about 70% of the total consumption.② Coating: it is mainly used to synthesize high-grade automotive paint, and its consumption accounts for about 10% of the total consumption. ③ Medicine: used for disinfection of wards, clothes, bedding and other pharmaceutical production, accounting for about 10% of the total consumption.④ Resin: used for synthesis of glycol, pentaerythritol, urea formaldehyde resin, polycondensal resin, melamine resin, ion exchange resin, etc., accounting for about 5% of the total consumption.⑤ Papermaking: synthetic paper intensifier. ⑥ Casting: used as sand stripping agent and synthetic casting adhesive. ⑦ Aquaculture: fumigation disinfectant. In addition, paraformaldehyde with low polymerization degree is used to synthesize vitamin A, perfume, terpene derivative, developing agent, ethylene resin softener and other auxiliary agents.

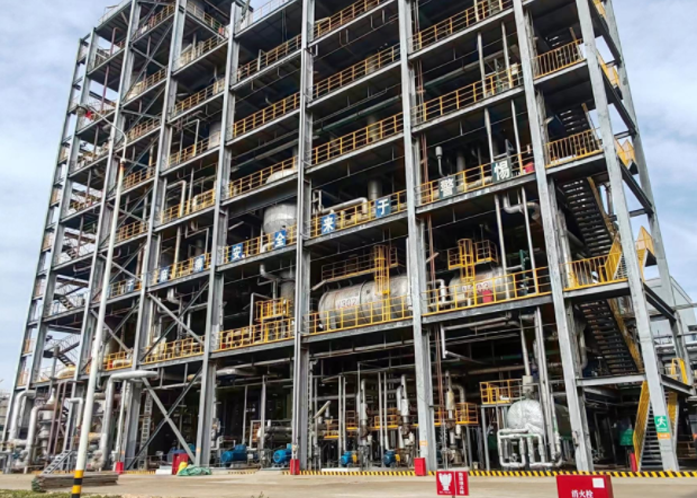

The key to the preparation of POM is to control the degree of polymerization, prevent the high polymerization of POM, shorten the drying and dehydration time, and improve the product yield. Its main production technology includes rake drying and spray drying.

Harrow drying method: the raw material formaldehyde is first concentrated and dehydrated to increase the concentration of formaldehyde by 37% to 65%, and then enters the harrow dryer for further dehydration to dry to powder discharge. The whole dehydration process is operated under negative pressure, and the evaporated condensate containing 10% - 15% dilute formaldehyde is returned to the formaldehyde section, which is configured to be 37% formaldehyde for export or to produce methylal and Urotropine.The process is intermittent operation, the feed of harrow dryer is 4-5m3 each time, the drying time is 4-6h, the production cycle is long, the production capacity is low, the product is powder block, the water solubility is poor, and the energy consumption is high.

Spray drying method: continuous production, concentrated formaldehyde spray time is short, can form a short linear chain of formaldehyde molecules, product structure is loose, water-soluble, suitable for large-scale production. But the spray granulation process investment is higher than the rake drying method.