The crude phenol raw material is first pumped into the crude distillation tower through the raw material pump for negative pressure dehydration and deslag. After dehydration and deslag, the mixed phenol fraction enters the raw material storage tank for rectification, and then is driven into the rectification kettle for negative pressure distillation separation. Through sampling Analyzing the content of the fractions, phenol, o-cresol, m-p-cresol, xylenol and phenol residue were obtained respectively.

This process can also use a continuous negative pressure distillation system, so the product quality will be more stable and the output will be relatively large.

Phenols have a variety of compounds, with the most important ones incl.

phenol(carbonic acid), and cresol(o-cresol, m-cresol and p-cresol); among them,

phenol is mainly used as the feedstock for di-phenol A production and phenol

formaldehyde production; o-cresol is widely used in the synthesis of resin,

pesticide, medicine, perfume, dyes, antioxidant and etc.; m-cresol is an very

important feedstock for the production of Vitamin E; p-cresol is widely applied

in the synthesis of BHT, the most employed antioxidant in the world. SL TEC

offers the technology of crude phenol purification with the phenol either from

coking phenol, or gasified phenol or alkylation liquid. Based on the facts that

the boiling points of the main product and the by-products are quite different @

certain condition and the boiling points will decrease with the reducing of the

pressure, SL TEC's technology lowers the separation temperature by reducing the

system system, distill, separate and purify to get high purity phenol

separately.

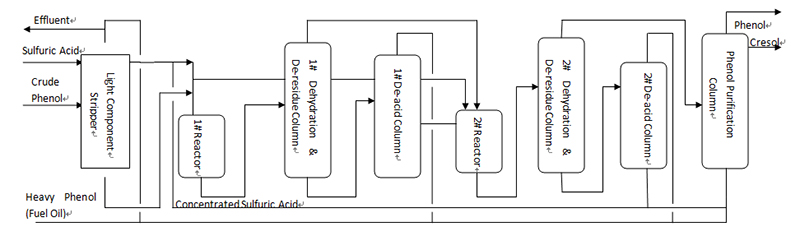

In the traditional crude phenol purification process, usually water removing,

residue removing, phenol purification units in batch are involved to separate

and purify phenol, cresol and other products. In this batch production, the

intermediate distillate between adjacent components requires repeated

rectification to increase the yield, thereby the productivity is low, the energy

consumption is low and only suitable for small production capacity; in addition,

as the phenol products have certain heat sensitivity, the repeated heating not

only decreases the total yield but also results in the unstable product quality.

While SL TEC provides a technology based on the achievements by cooperation with

Tianjin University. It is based on continuous vacuum distillation, uses DCS

control system to optimize operation. Its advantages include the followings:

1.

The yield and the product quality is obviously advanced.

2. Thks to the

auto-protection and chain shutdown system, the production is very stable, the

product quality is also stable and the production flexibility is big.

3. It

successfully separates sulfuric acid and heavy components phenol to realize the

100% recovery of sulfuric acid, thereby the consumption is largely redyced;

meanwhile graphite reactor and glamel reaction equipment are employed, which

avoids the corrosion of sulfuric acid catalyst to the equipment and therefore

decreases the equipment investment.

As below are shown the performances of 40,000TPA Crude Coking Phenol

Purification Project for references.

1. Product Specification

a. Phenol

Specification

S/N | Item | Index |

1 | Crystallization point, oC | 40.6 |

2 | Solubility Test[(1+2) Absorbance] | 0.03 |

3 | Moisture, % wt | 0.10 |

b. Cresol specification

S/N | Item | Index |

o-Cresol | m-Cresol and p-Cresol | Industrial Cresol |

1 | Appearance | White to light tawny crystal | Colorless to brown transparent liquid | Colorless to chocolate-brown transparent liquid |

2 | Density @ 20oC, g/cm3 | - | 1.03-1.04 | 1.03-1.05 |

3 | Moisture, %wt ≦ | 0.3 | 0.3 | 1.0 |

4 | Neutral Oil Test (Turbidimetric method), # ≦ | 2 | 10 | 10 |

5 | Phenol content, % wt ≦ | - | 5 | - |

6 | o-cresol, % wt ≧ | 99.0 | - | - |

7 | 2,6-Xylenlo, %wt ≦ | - | - | - |

8 | m-Cresol, % wt ≧ | - | 50 | 41 |

9 | Cresol + Xylenlo, % wt ≧ | - | - | 60 |

10 | Tricresol, % wt ≦ | - | - | 5 |

Note 1: in liquid state, o-cresol is colorless or slightly colored transparent liquid

Note 2:cresol includes all isomers of C7H8O; xylenlo includes all isomers of C8H10O.

Note 3: tricresol includes all isomers of C9H12O. |

2. Performances of 40,000TPA Phenol Purification Plant

S/N | Item | Unit | Index | Remark |

I | Production Capacity | | | |

| Crude Phenol Purification Plant | kt/a | 40 | |

II | Product Plan | | | |

1 | Phenol | t/a | 3030.48 | |

2 | Cresol | t/a | 19288.8 | |

3 | Fuel Oil | t/a | 13564.08 | |

III | Annual Running Days | days | 300 | 7200 hrs |

IV | Consumption of RM and Auxiliaries | | | |

| Crude Phenol | t/a | 37677.6 | outsourcing |

V | Consumption of Utilities | | | |

1 | Fresh Water | t/a | 82034 | Living and others |

2 | Electricity(10kV/0.4kV/220V) | kWh/a | 355.68×104 | |

3 | Natural gas | Nm3/a | 622.08×104 |

|