Hydrogen Peroxide Plant Process Options | SL CHEMTECH EPC Solutions

Complete Hydrogen Peroxide Plant Design Based on Proven & Advanced Technologies

SL CHEMTECH offers comprehensive EPC solutions for Hydrogen Peroxide Manufacturing Plants, providing clients with multiple process options to meet different production capacities, investment scales, and technical requirements.

Our engineering team has extensive experience in designing and delivering Hydrogen Peroxide Plants based on the most widely recognized and industrially proven processes, ensuring safe, efficient, and cost-effective operations.

Hydrogen Peroxide Production Process Options

We offer the following mainstream Hydrogen Peroxide Process Technologies, each with distinct advantages to suit different project needs:

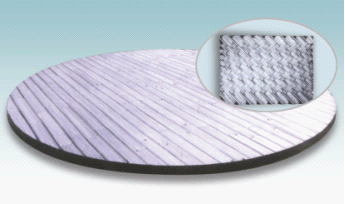

The Fixed Bed Process is a mature and widely adopted technology for hydrogen peroxide production, especially suitable for small to medium-scale plants.

Simple and stable process operation

Long catalyst lifespan with low maintenance

Lower initial equipment investment

Suitable for regional or small industrial-scale projects

Proven reliability with extensive global references

The Fluidized Bed Process represents advanced technology, ideal for large-scale, high-efficiency hydrogen peroxide production plants.

High production capacity with superior catalyst efficiency

Excellent heat and mass transfer performance

Longer catalyst life and reduced operational costs

Continuous, stable production with high plant reliability

Environmentally friendly with improved energy efficiency

3. Entrainment Bed (Suspension Bed) Hydrogen Peroxide Process

The Entrainment Bed Process, also known as the Suspension Bed Process, is a relatively modern technology combining some advantages of fixed and fluidized bed systems.

Improved mass transfer efficiency compared to fixed bed

More flexible design for medium to large-scale production

Enhanced catalyst utilization

Balanced investment and operational performance

Increasingly adopted in new plant projects worldwide

Process Selection Comparison

| Process Type | Production Scale | Catalyst Efficiency | Investment Cost | Technical Complexity | Typical Applications |

|---|

| Fixed Bed Process | Small to Medium | Standard | Low | Simple | Regional plants, small/medium projects |

| Fluidized Bed Process | Medium to Large | High | High | Advanced | Large-scale industrial projects |

| Entrainment Bed Process | Medium to Large | High | Moderate | Moderate | Flexible industrial plant solutions |

Why Choose SL CHEMTECH for Hydrogen Peroxide Plant Projects?

As an experienced Hydrogen Peroxide Plant EPC Contractor, we provide:

Process selection consultation tailored to your project needs

Complete engineering design and technical support

Full-scope equipment supply and construction services

Project management, commissioning, and training

Reliable after-sales technical support

Whether you need a Fixed Bed, Fluidized Bed, or Entrainment Bed Hydrogen Peroxide Plant, SL CHEMTECH delivers safe, efficient, and customized plant solutions.

View our successful projects!